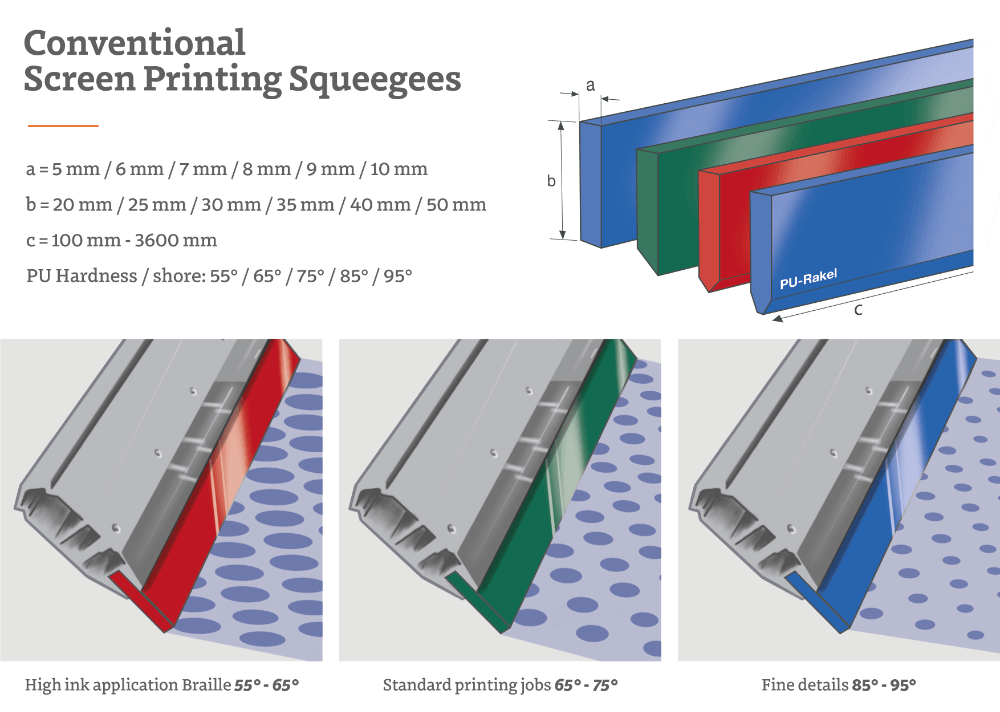

Conventional Screen Printing

More information

Our conventional screen printing squeegees are made of polyurethane, which has been specially developed for the different requirements of screen printing. The conventional screen printing squeegees are available in all common shapes, bevels and combinations of different shore hardnesses. All conventional screen printing squeegees are color-coded for better differentiation of the various hardnesses.

Configurator

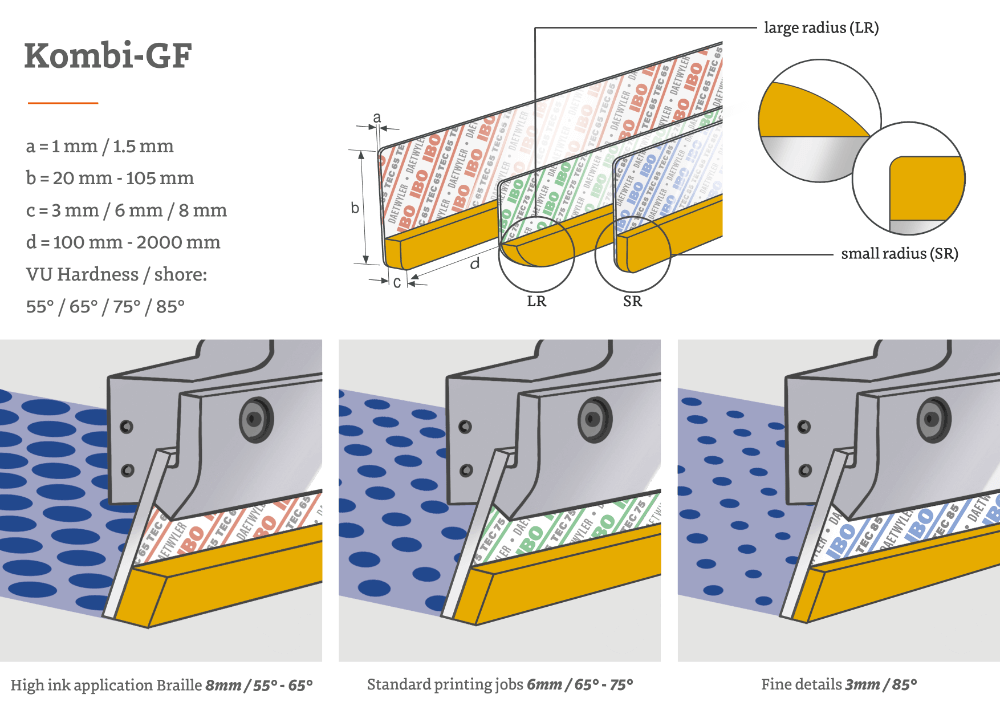

Kombi-GF

More information

Tolerance

a= +/- 0.2mm

b = +/- 0.25mm

d = +/- 0.5mm

Cutouts = +/- 0.25mm

The Kombi-GF was specially developed for the requirements of flatbed screen printing machines. Our combination screen printing doctor blades consist of a fixed base body, to which a small polyurethane strip is attached over its entire length using a bonding process.

The base body is made of high-quality rust-resistant strip steel. The rust-resistant strip steel has excellent stiffness and elasticity. In addition, the stainless strip steel has good electrical conductivity, which under certain conditions can help to dissipate static electricity.

We make no compromises in terms of the quality of our polyurethane strip so we only use Vulkollan®, which has very good mechanical and high dynamic load-bearing capacity. The low abrasion values, high tear resistance, good tear propagation resistance, excellent compression deformation and high rebound resilience are particularly noteworthy. Vulkollan® is manufactured without the use of plasticizers and fillers, resulting in the highest possible chemical resistance. To make it easier to distinguish between the different Shore hardnesses, the base bodies are both color-coded and marked in writing.

The big difference between our combination screen printing squeegee and a conventional screen printing squeegee is that all conventional screen printing squeegees deform after a short time of printing.

This makes it very difficult to produce a constant and reproducible printing result. The stable base body of the combination screen printing squeegee prevents the polyurethane strip to deform. As a result, a constant and reproducible printing result is achieved over a much larger production window.

Configurator

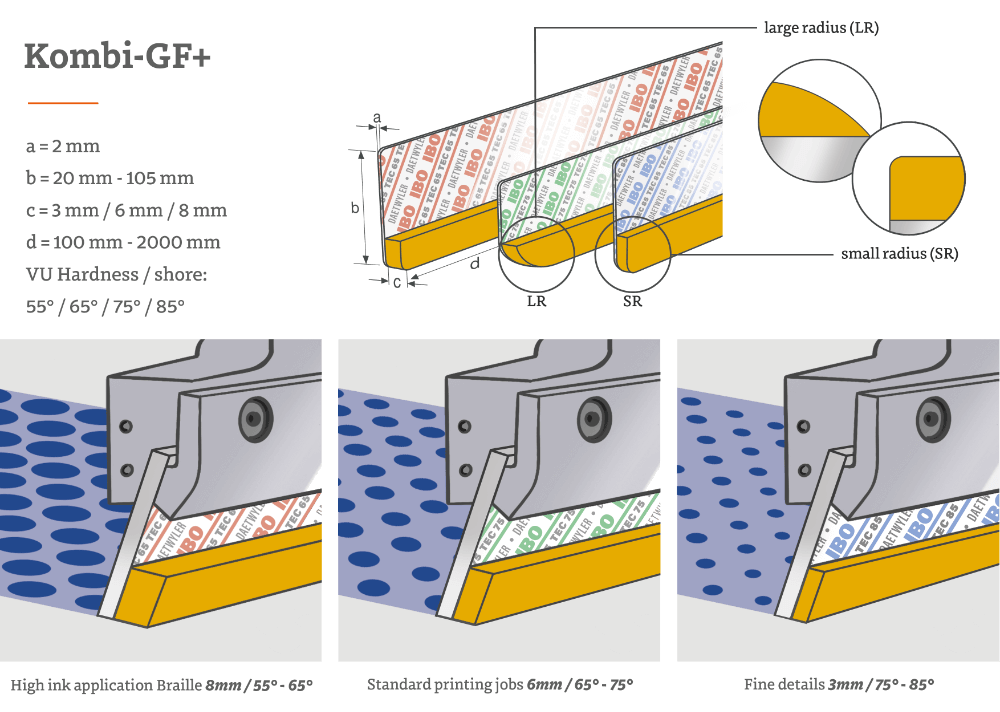

Kombi-GF+

More information

Tolerance

a= +/- 0.2mm

b = +/- 0.25mm

d = +/- 0.5mm

Cutouts = +/- 0.25mm

The Kombi-GF+ was specially developed for the requirements of rotary screen printing machines in the printed electronics segment. Our Our combination screen printing squeegees consist of a solid base body, to which a narrow polyurethane strip is attached over its full length through an adhesive process.

The base body is made of high-quality glass-fiber reinforced plastic. The glass fiber-reinforced plastic has excellent stability and elasticity.

We make no compromises in terms of the quality of our polyurethane strip so we only use Vulkollan®, which has very good mechanical and high dynamic load-bearing capacity. The low abrasion values, high tear resistance, good tear propagation resistance, excellent compression deformation and high rebound resilience are particularly noteworthy. Vulkollan® is manufactured without the use of plasticizers and fillers, resulting in the highest possible chemical resistance. To make it easier to distinguish between the different Shore hardnesses, the base bodies are both color-coded and marked in writing.

The big difference between our combination screen printing squeegee and a conventional screen printing squeegee is that all conventional screen printing squeegees deform after a short time of printing.

This makes it very difficult to produce a constant and reproducible printing result. The stable base body of the combination screen printing squeegee prevents the polyurethane strip to deform. As a result, a constant and reproducible printing result is achieved over a much larger production window.

Configurator

Our headquarters

Daetwyler IBO Tec GmbH

Loog 21

23611 Bad Schwartau

Germany

Fax: +49 451 38 444 981